case-studies-test

Bellrock PLC.

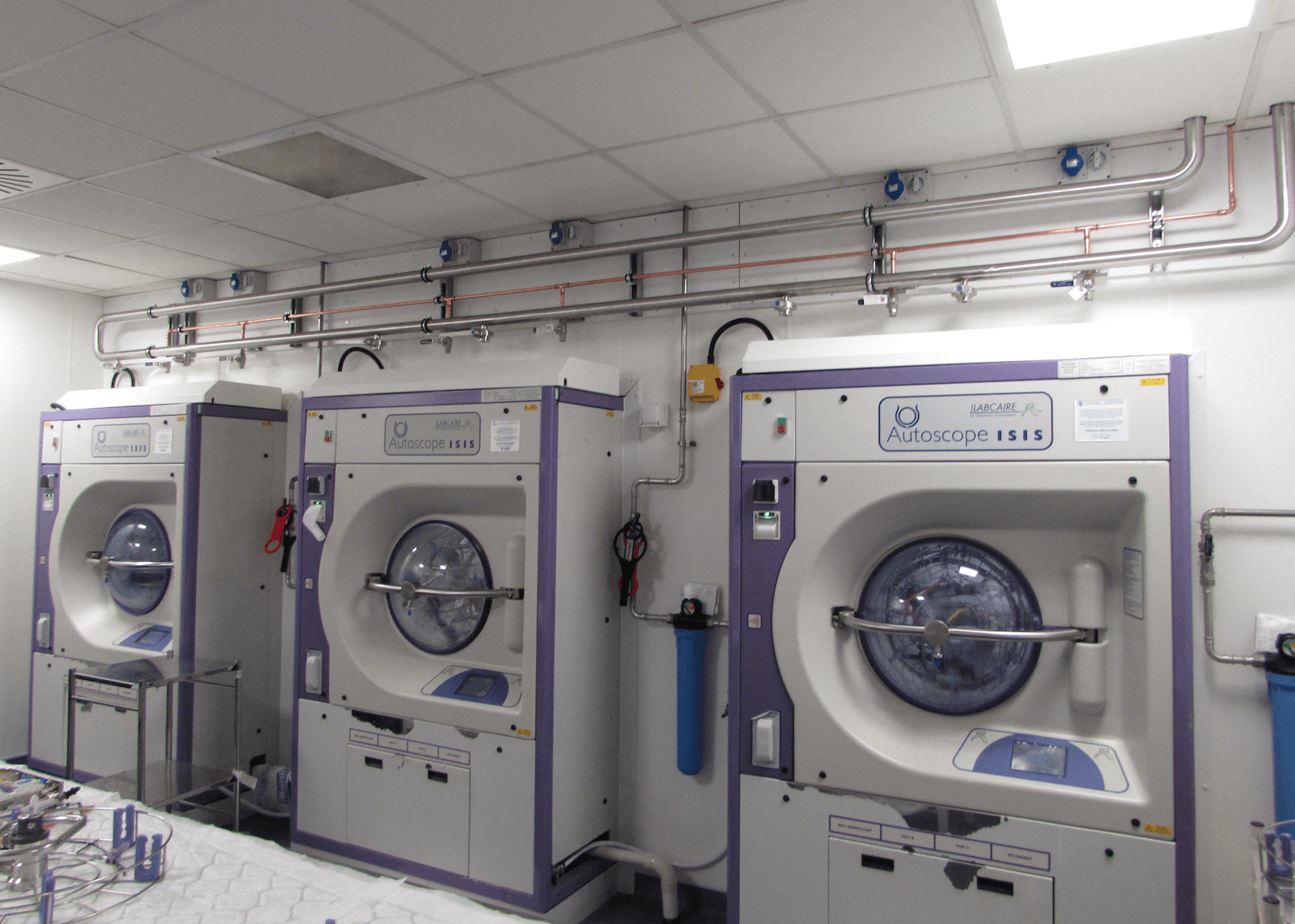

Whittington Health NHS Trust

Whittington Health NHS Trust

Heathrow MBBR

South East Water (various sites)

London Project

WHERE TO FIND US

Registered Office: The Stables, 23b Lenten Street,Alton, Hampshire,England, GU34 1HG Irish Office:Glenhouse, Charleville,County Cork, P56 YT59

CONTACT

01420 277 987info@hanevo.com

Site designed, built and powered by Halo Marketing Solutions.